Die cutting machine

Die cutting means molding that is accompanied by a blade and a fold line

Types of die cutting:

1- Jaw die cutting

2- Bobs die cutting

3- Rotary die cutting

4- Pincushion die cutting

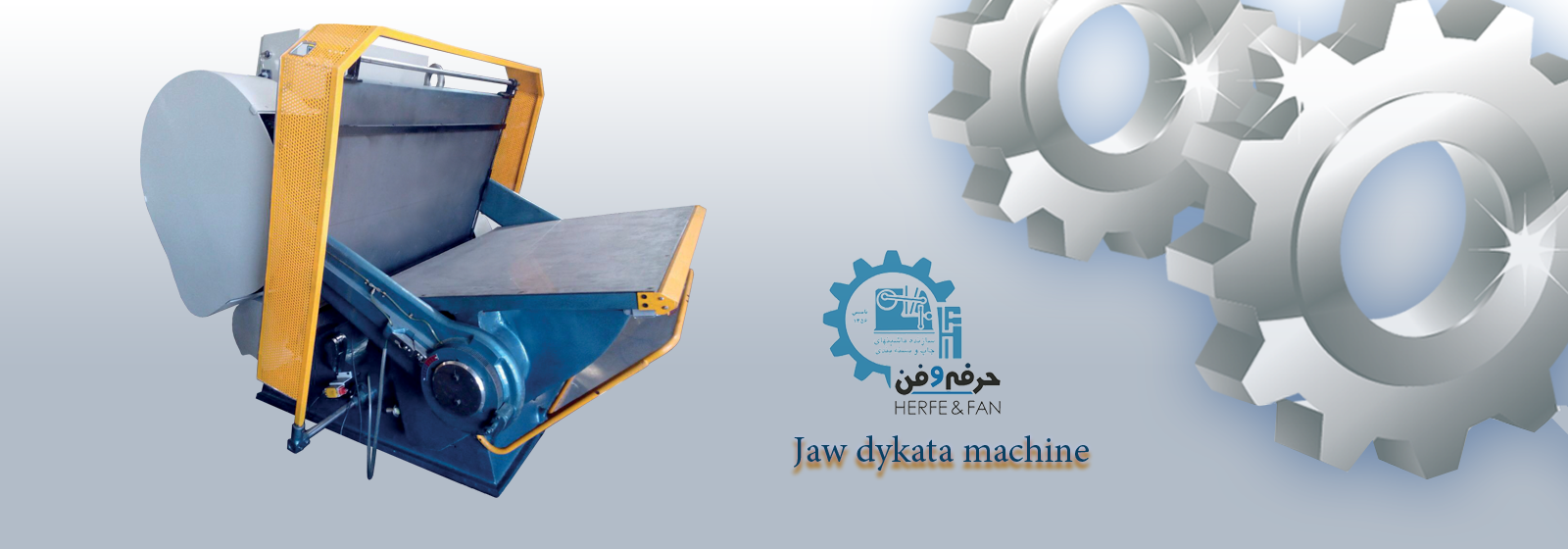

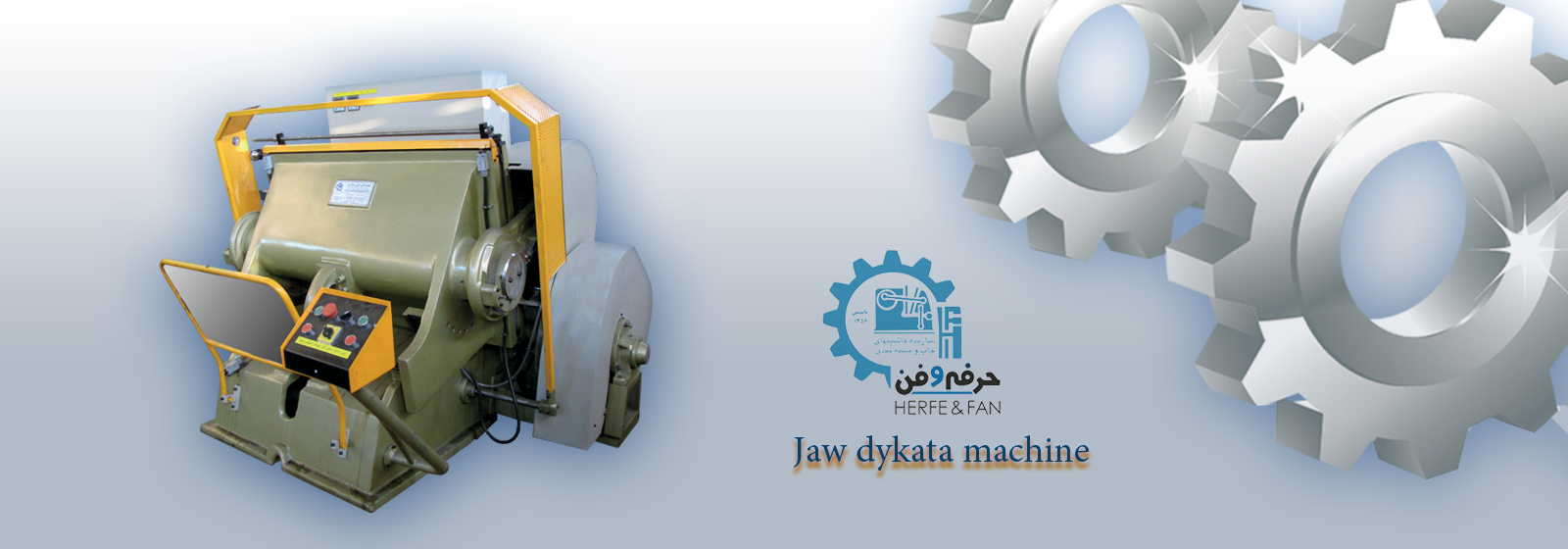

Jaw die-cutter:

This machine is one of the most widely used in the box and carton making industry. One of the obvious advantages of this machine is high accuracy in lamination and under-gluing work to select the desired line. Due to the fact that the mold is placed inside the frame on a fixed plate and the sheet is placed on the goni (moving plate), the movement of this machine is reduced to zero, and this is one of the advantages of this machine. The jaw die-cutter is operator-oriented and only requires one operator during operation and is usually fast. To see the machine video, please refer to the gallery.

Loading and sending jaw dies

Jaw die specifications

1- Has anti-oil brake and clutch pads which are important for the safety of the device

2- Has standard safety in several places of the device

3- Has magnetic microswitches

4- Uses the world's leading technology

5- Has a pause from 0 to 30 seconds

6- Device safety certificate from the Ministry of Labor and Health of the Islamic Republic of Iran

00

| Device dimensions | Machine weight | Maximum blows per hour | Engine power |

| 80*120 | 4000 Kilogram | 1900 | 4 Kilowatt |

| 90*130 | 4300 Kilogram | 1700 | 5/5 Kilowatt |

| 100*140 | 4700 Kilogram | 1500 | 5/5 Kilowatt |

| 130*170 | 12000 Kilogram | 1200 | 8 Kilowatt |

Jaw die cutting machine video

.jpg)

.jpg)

20 km of Khavaran Road, Qayyamdasht

20 km of Khavaran Road, Qayyamdasht